Watch Anatomy

Watch Anatomy

Watch Parts

Case

Crystal

Dial

Luminosity

Hands

Buckles

Bezels

Water Resistance

Helium Escape Valve

Shock Resistance

Movement

The engine of the watch.

Crown

The mechanism that allows for the winding of the movement and adjustment of functions like date and time. To enhance water resistance, crowns can screw into the case to form a seal against moisture or water.

Pusher

Case attachment that controls functions, such as the chronograph or date adjustment.

Lugs

Case attachment that allows for a strap or bracelet to be attached to the watch case.

Rotor

Oscillating weight that winds an automatic watch when worn.

Strap

Commonly a leather or rubber attachment that secures a watch to the wrist. Metal attachments, generally made from stainless steel or gold, are referred to as bracelets.

Subdial

A small dial set within the main dial, which is used to display an additional complication such as chronograph readout, seconds, or date.

Exhibition Caseback

Fitted with a mineral or sapphire crystal to show movement finishing.

Hour Marker

Hour indicator applied or painted on the dial.

Case

Holds the movement and protects it from the elements. It can be made from different metals and comes in different shapes.

Cases can be made from a variety of materials that include:

Platinum

- Considered noble, rare and hard

- Hard to work with

- Stamped as “950”

- 4.5 on Mohs Scale

18K Gold

- Yellow, rose and white. K is karat weight

- 24K is purest and softest

- 18K is 75% gold

- 2.5 – 3 on Mohs Scale

14K Gold

- Rarely used in Swiss watches

- 585 parts gold

- 3.0 – 3.5 on Mohs Scale

Gold Plate

- Gold over base metal

- Wears off over time

- Rarely used in Swiss watches

Stainless Steel

- Most popular

- Can be refinished to original state

- Harder than gold to scratch

- 5.5 – 6 on Mohs Scale

Titanium

- Lightweight and durable, space-age material

- Hypoallergenic

- 6.0 on Mohs Scale

Ceramic

- Lightweight and durable, space-age material

- Scratched only by diamond

- 8 – 8.5 on Mohs Scale

Tantalum

- Dark, dense, hard

- Highly resistant to corrosion

- 6.5 on Mohs Scale

Tungsten Carbide

- Dense metal-like substancel

- High strength, hard and rigid

- 7.5 on Mohs Scale

PVD

- Process by which a layer of material is bonded to base metal

- Improves hardness and wear resistance

Diamond-like Carbon (DLC)

- Bonded to the base watch metal

- Nearly as hard as natural diamond

- Slicker than Teflon

Crystal

This is the “glass” that covers the face of the watch and protects it from dirt and water. There are three major types of crystals produced and used in watchmaking:

Acrylic

Similar to plastic, acrylic is the most affordable type of crystal but also the most prone to scratching and can crack if impacted. Minor scratches can be buffed out and acrylic crystals can be molded into elaborate shapes that sapphire and mineral crystals cannot.

Mineral

Mineral crystals are simply made of glass. They have been used in watchmaking for hundreds of years. Mineral crystals are relatively easy to scratch, and these scratches cannot be buffed out. They are inexpensive compared to sapphire crystals, usually costing less than one hundred dollars to replace if damaged.

Synthetic Sapphire

This transparent, lab-grown element has exactly the same chemical composition of natural sapphire but at a fraction of the price. It is used because sapphire is the second hardest known element, right after diamonds. This makes it extremely scratch resistant and useful for watch crystals. The downside to this is that it can chip or shatter if impacted. If this happens, microscopic particles of sapphire can get into the movement and act as an abrasive, causing damage. Sapphire is also the most expensive type of crystal, costing several hundred dollars to replace. The majority of watches imported from Switzerland have sapphire crystals.

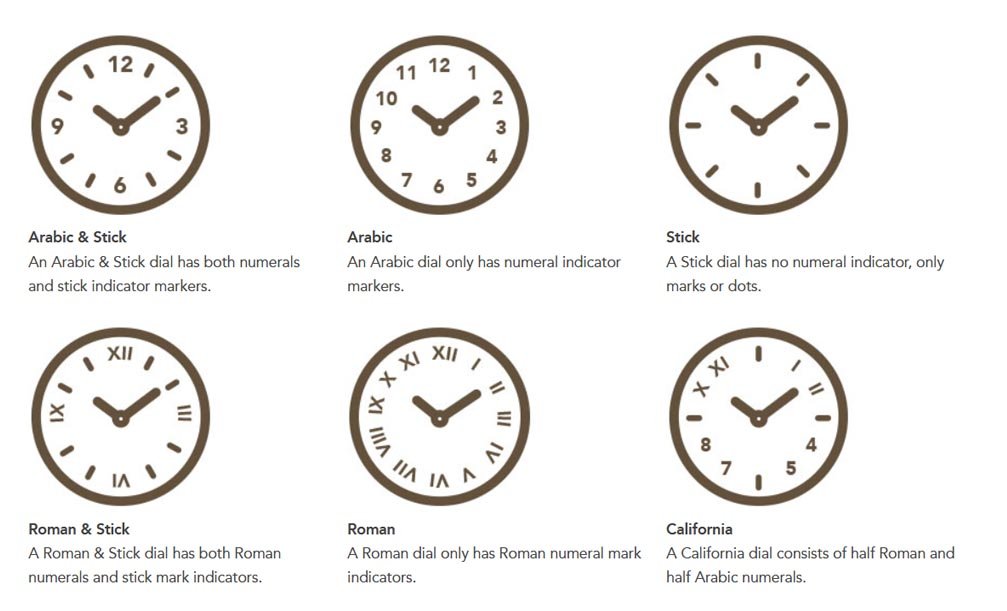

Dial

On the face of the watch, there are many different ways that a dial can be marked. The below shows some of the most popular types:

Luminosity

Many watches have glow-in-the dark hands and hour markers. The substance used for this purpose has evolved over the years. Originally, Radium was used in the 1950’s but was found to be highly radioactive and was replaced with a substance called Tritium. Tritium had much lower levels of radiotoxicity and was considered a much safer alternative to Radium. You can tell if a watch has Radium or Tritium markers because it will have the letter ‘T’ or ‘R’ printed on the dial, usually flanking the country of origin(ex. T-Swiss Made-T, or R-Swiss Made-R).

Cleaning a water-resistant watch:

- Use a soft damp cloth to clean the head of the watch and then wipe off with a dry soft cloth.

- Metal bracelets can be cleaned by using mild soapy water and a soft toothbrush.